Page 1 of 1

Options for reducing quench clearance

Posted: Tue Jun 15, 2010 10:42 am

by cgrey8

What I'm finding is that most stroker kits have pistons that aim at a deck clearance of around .016" or in other words, the pistons at TDC are .016" in-the-hole. Add another .040" for the head gasket and you have a very loose .056" for a quench area assuming a standard flat-top piston. Ideal quench is in the .025-.035" range. So to get that kind of quench from a stroked 302 block, I need to:

- Deck the block down .025"

- Install a thinner head gasket

- A combination of the two

I've heard of people installing thinner .025" head gaskets, but I can't find anybody that sells them...at least not via webpage searches. If I could find some thinner head gaskets, that would mean I'd only need to deck the block by .010" which sounds a lot more reasonable.

If I could find a 331 stroker kit that pushes the pistons right to the deck or slightly above it, that would reduce the amount I need to deck the block by even less while using a standard thickness gasket.

Any thoughts or opinions on the best ways of getting a ~.030" quench?

Re: Options for reducing quench clearance

Posted: Tue Jun 15, 2010 4:06 pm

by MalcolmV8

Interesting. Why are stroker kits made this way? Is there some design reasoning behind it? What about a domed piston? would that solve your problems?

Have you chatted with any local high performance shops to see how they deal with this issue when building stroker motors?

Re: Options for reducing quench clearance

Posted: Tue Jun 15, 2010 5:13 pm

by cgrey8

Best I can figure is the stroker mfgs assume that if you are doing a stroker upgrade that you'll also be decking the block at the same time. So they design the piston to not pop higher than most people would want/be comfortable with???? That's just a guess...

BTW, a guy over on the EECTuning.org site posted a link to a website that sells thinner head gaskets:

COMC5511-027: .027" Cometic MLS Head Gasket

It's a bit pricey though.

Re: Options for reducing quench clearance

Posted: Tue Jun 15, 2010 9:13 pm

by MalcolmV8

I was expecting a lot higher. Those gaskets are pretty cheap all things considered. When you get into high performance stuff prices go way up. I won't even mention how much the head gaskets for my Cobra where lol.

So what about a domed piston? will that not fix your issue? If not I'd deck the block to fit your stroker kit so it leaves you with more head gasket options especially if it will be stock thickness gaskets you'd be looking for. Might even call a few of the companies that make those stroker kits and see what they have to say about it.

Re: Options for reducing quench clearance

Posted: Wed Jun 16, 2010 6:17 am

by cgrey8

If cost were no issue, the CORRECT answer is to get custom pistons that locate the piston where I want. But that would be $700 just for custom pistons and I believe that forces me into a forged piston, not a hypereutectic piston. Hypereutectics are better for fuel economy & emissions because they fit tighter in the bore and are lighter. If I can find other ways to meet my goals without spending that much money, I'd like to explore those options and learn the pros and cons so I can make a more informed decision as to what the best course of action is.

As for the pop-up piston, that will increase compression, but most of the time, they only dome the piston in the area of the compression chamber, not in the area of quench. My intention isn't to increase compression, but rather to tighten the quench area. With cast iron heads running pump gas, I'm already a little concerned that my compression is going to be too high. And yes, a thinner head gasket or higher piston height does have the effect of increasing compression. Add to that, domed or pop-up pistons don't work nearly as well for fuel economy and emissions as flat-top pistons do. The raised area adds surface area to the compression chamber which adds friction and thus slows down the swirl. Less swirl promotes predetonation...exactly what tighter quench is supposed to help reduce by maintaining a high level of swirl in the chamber right at the point of maximum compression. The pop-ups also gives more surface area for fuel to stick to instead of staying atomized into the air...at least that's what articles I've read say about pop-up pistons. Add to that, the extra aluminum used in the pop-up adds weight. How much of those points are conjecture/opinion and how much is fact, I don't know. But it does seem like a common opinion amongst article-writing so-called experts.

The one problem I envision as a possibility with decking the block too far is intake fitment. If the heads drop too low, either due to thinner gasket OR decking, the intake bolts and ports may not line up correctly. I don't know at what point this becomes an issue, but it is something I envision could bite me when I go to final assembly and discover that the lower intake doesn't want to fit just right and the gaskets aren't "squishy" enough to make up the difference. I'm wondering if I'd need to deck the intake landings to get the intake narrower so it'll fit correctly. Thoughts?

Re: Options for reducing quench clearance

Posted: Wed Jun 16, 2010 7:14 am

by Dave

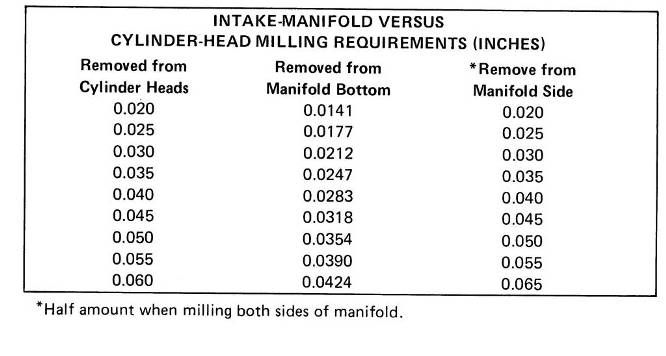

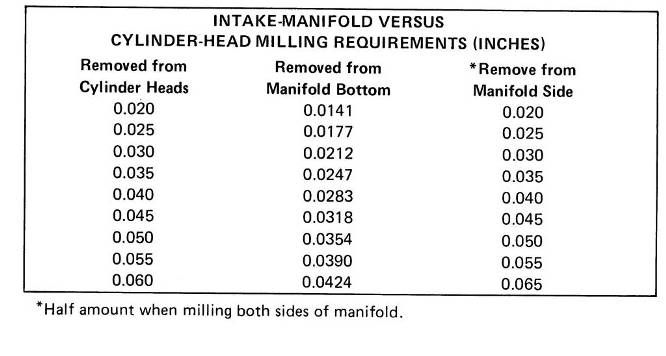

Chris, looking at a lot of the early 302's and most had the pistons down in the hole .010-.020". There is a chart showing what has to be milled off the manifold to compensate for milling/decking the block. Basically calls for milling half the amount that the heads milled off each side of the manifold and even a slight amount off the bottom of the manifold. Somethink like .010" shouldn't cause a problem with alignment. Sounds like an interesting project.

Dave

Re: Options for reducing quench clearance

Posted: Wed Jun 16, 2010 7:48 am

by cgrey8

If you find such a chart on the Internets, please post as that is relevant to what I'll be dealing with. Whether I used the .027" gasket or decked the block, it's the same result from the perspective of the intake.

Re: Options for reducing quench clearance

Posted: Wed Jun 16, 2010 7:59 am

by Dave

Chris, the chart is actually in the "How to rebuild a SBF" by Tom Moore. I can sure scan it in and send your way.

Dave

Scanned it in!

Re: Options for reducing quench clearance

Posted: Wed Jun 16, 2010 8:39 am

by cgrey8

Ok, that looks like what I need. Regardless whether I use the thinner gaskets or deck the distance I need while using .040" gaskets, I believe the heads will drop by about .026" on both sides which sounds like enough that intake machining will be necessary.

And I suspect the block/intake decking will be cheaper than $700 for custom pistons. So I think I'll plan on that being the way I go. I'll take the heads, block and intake in to get machined when I go. But until then, I'm still in search of a stroker kit that, by default, locates the pistons higher than .016" from the deck.

Re: Options for reducing quench clearance

Posted: Fri Jun 18, 2010 8:55 pm

by cgrey8

I talked to a guy that seemed to really know what I wanted to do and he gave me some really great info. He said first off I need to be looking at forged pistons. Because so many people want forged, there's a FAR greater selection of forged pistons than there are hyptereutectic. He was able to find a 331 forged piston that is even with deck height, and another that raises above the deck. Forged is a little more expensive, but not as much as the added cost of decking the upper intake to fit after decking the block and/or using thinner gaskets. The other benefit to forged pistons, he said, is forged is actually lighter (I thought they were heavier). He gave an example of one piston that pops the piston up to deck height as 590g as compared to the hyptereutectic that's in the hole .015" and is 600g. So even though there was more material on the forged piston, it was still lighter.

So, it looks like I'm going with forged pistons. I can get almost exactly what I want. He said before I order though, I'll want to measure the ACTUAL deck height of my block. Design deck height is 8.200" from centerline of the crank to the deck. But he said some blocks are as high as 8.210". Some are slightly below 8.200". That's why some engines in 100% stock form just perform better than others do. Once I know what my actual deck height is, I can order a set of pistons that maximizes the piston height so I don't have to deck the block any more than is necessary just to square it up and get the twist out of it.

Re: Options for reducing quench clearance

Posted: Fri Jun 18, 2010 9:08 pm

by MalcolmV8

Great info there Chris. Glad you've found what you want. I must say I was very surprised earlier in the thread when I saw you were not going with forged pistons. I've always believed them to be lighter too but I didn't have any data to support that so I never said anything. Forged pistons will take one heck of a beating too if you ever decide to up power goals in the future. Piston to wall clearance though is something you will decide at time of machine work and I imagine you'll keep yours fairly tight giving your power goals and plans for the motor.

When you get your new pistons you'll see a chart that shows machining specs that comes with them and for boosted applications, nitrous etc. they show increased ring gaps and various other tolerances that need to be set.

When I rebuilt the motor on my Cobra I increased piston to wall clearance to allow for more heat expansion of the pistons since my power goals where high and I had already ruined one motor by expanding the piston to much and scuffing the piston and making tiny marks on the cylinder. My machine shop warned me I risked having piston slap noise on cold start up with the increased piston to wall clearance but knock on wood I've never had any

Re: Options for reducing quench clearance

Posted: Fri Jun 18, 2010 9:16 pm

by cgrey8

I asked him about that while on the phone and he said they make it simple. Bore the block .030" over and when I purchase the piston, it is already sized for a .030" overbore. Hypereutectic requires .0025" clearance while forged requires .004" clearance (cold). Forged pistons will expand further when hot hence the wider limit. He said when the engine is up to temp, the clearance should be exactly the same between the hypereutectic and forged. He said if I opt for the teflon side-coating, I can drop the clearance by .001" to get an even tighter fit. But the teflon coated pistons are about $20 more/piston. He said while they do provide better protection, he's never heard that the teflon side-coating being an efficiency improvement over oil at cruising loads. It's mostly done to keep the engine quieter when the engine is cold. That's it...

Re: Options for reducing quench clearance

Posted: Fri Jun 18, 2010 9:24 pm

by MalcolmV8

I suppose every machine shop is different but mine required the pistons in hand and each bore was matched to a piston. My pistons where numbered for a specific cylinder. I guess depending on how accurately and to what decimal point of accuracy you want to get down to.

Re: Options for reducing quench clearance

Posted: Fri Jun 18, 2010 9:52 pm

by Dave

MalcolmV8 wrote:I suppose every machine shop is different but mine required the pistons in hand and each bore was matched to a piston. My pistons where numbered for a specific cylinder. I guess depending on how accurately and to what decimal point of accuracy you want to get down to.

That's the same way I have always heard. Really don't think Chris is going to be cranking on the motor like some do

Dave