This question is on my 03 Cobra with a 4.6. I know there's a lot of really smart guys on here working with the 302s and 4.6s so I thought I'd reach out here.

Reason for change:

First I'll preface this and let you know my main reason for looking into cams is purely the awesome sound. Especially at idle. I know it's an expensive mod just for sound but I've had the car for almost 12 years now so I have to change things up from time to time to keep it interesting.

Relevant specs on car:

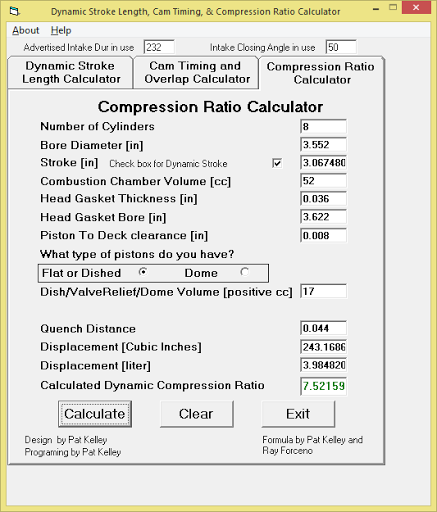

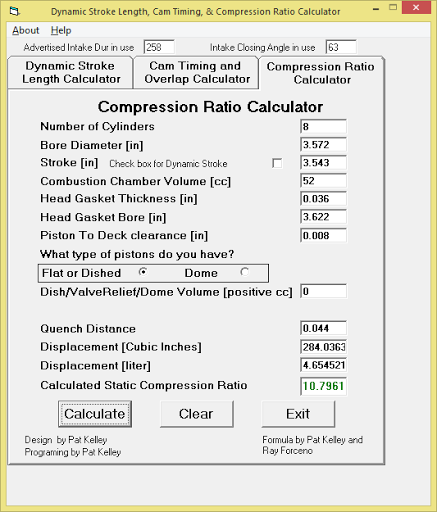

I rebuilt the motor in 09 and went with -19cc dished pistons giving me a static CR of 8.1:1. Dumbest thing I've ever done with the car {punch self in face LOL}. That low CR killed throttle response, HP, and gas mileage. It is what it is and I don't plan on rebuilding the engine right now so I live with it.

The car currently has a 2.9 Whipple supercharger and is tuned for both 91 pump gas with methanol injection and also for E85. I switch back and forth due to the PITA of getting E85.

The car is at 27.5 PSI of boost and dynos around 705 whp or there about on E85 (without spraying the nitrous). It still has the stock exhaust manifolds on it so I'm sure that's a restriction. I'll be switching to long tubes this winter which should drop the boost down a few PSI and increase HP a little bit.

Concerns:

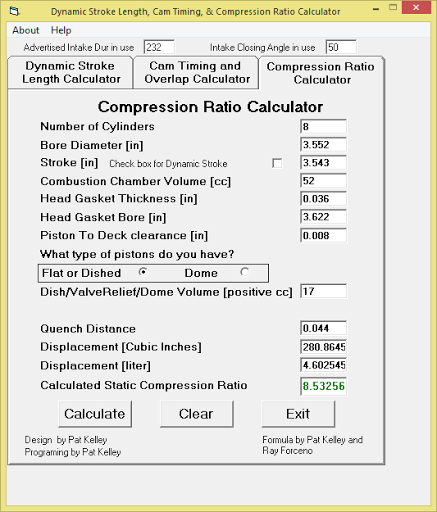

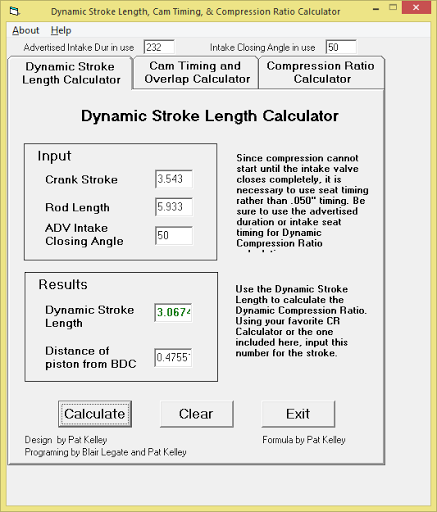

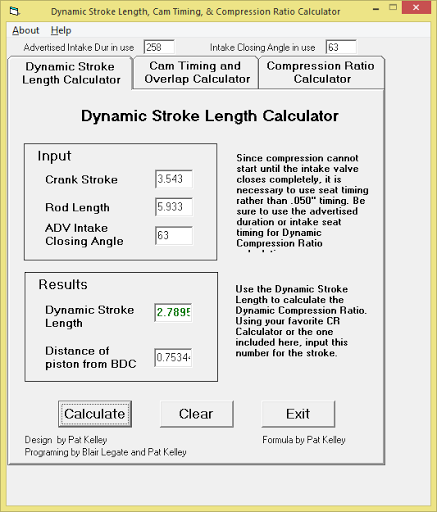

So my huge concern is that I already have such low CR. Adding more aggressive cams usually lowers the dynamic CR so I'm afraid that putting in some cams will kill HP. While I don't necessarily expect a huge (if any) HP increase with some cams I certainly don't want to kill HP just for the sound of cams.

Also a huge concern is drivability since I do 99% of driving on the road with this car. Granted its not my primary daily drive but a fun weather driver so I can live with a little bit of not so stock. I don't want it to be like a POS though dying at idle, stalling on take off, bogging and then jerking forward at low RPMs and basically just a horrible street car.

I've asked around on the forums and some local guys and I get everything from "Crower Stage 3 cams drive like stock if your tuner knows what he's doing" to "they sucked so bad I went back to stock cams". So that's kind of up in the air. I will say I got a lot more responses of "it drives like close to stock" than not. As for tuner... well I tune my own stuff so we'll see how that goes

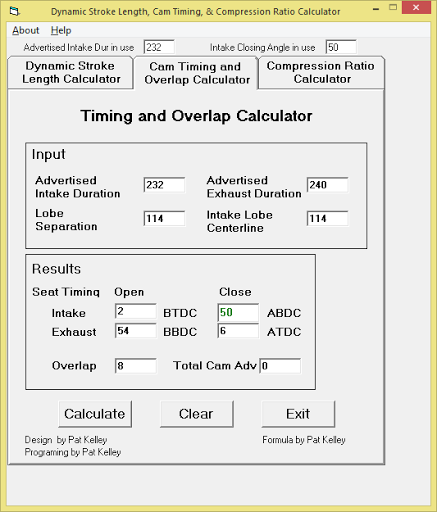

OK so googling around this is the best I could find for what the specs are on the stock 03 Cobra cams.

INT: 190 deg @ .050/.394 lift

EXH: 196 deg @ .050/.397 lift

114 LSA, no advance

Looking around I see the main two companies making cams for the 03 Cobras that guys are getting is Crower and Comp. Listening to youtube videos I wouldn't even consider Crower Stage 2 cams. They sound so close to stock idling it would be a waste of my time and money. Stage 3 is where it sounds awesome.

For reference here are the Crower Stage 2 specs

INT/EXH - Dur @ .050” Lift: 206°/206° RR: 1.8/1.8 Gross Lift: .475”/.475” LSA: 114° RPM: Idle to 5900 Redline: 6400

Crower Stage 3 (the ones I'm considering)

INT/EXH - Dur @ .050” Lift: 212°/212° RR: 1.8/1.8 Gross Lift: .484”/.484” LSA: 114° RPM: Idle to 6200 Redline: 6700

The Comp cams Stage 3 sound even nastier in youtube videos so I assume this an even less street friendly cam. Here are the three Comp cam specs for comparison sake.

Comp - 106260

RPM - 1200 to 5800

Duration Intake 257

Duration Exhaust 259

Lobe Seperation 116

Dur @ .050 lift intake: 222 exhaust: 224

Intake Centerline 114

Valve lift intake: 0.475 exhaust: 0.45

Comp - 106360

RPM - 1500 to 6000

Duration Intake 265

Duration Exhaust 267

Lobe Seperation 116

Dur @ .050 lift intake: 230 exhaust: 232

Intake Centerline 114

Valve lift intake: 0.475 exhaust: 0.45

Comp - 106460

RPM - 2000 to 6400

Duration Intake 273

Duration Exhaust 275

Lobe Seperation 116

Dur @ .050 lift intake: 238 exhaust: 240

Intake Centerline 114

Valve lift intake: 0.475 exhaust: 0.45

Another concern is air intake temps. I'd never heard of this till I started researching cams but it appears reversion is a real issue. With the overlap you can have the exhaust pressure pushing into the intake manifold in idle and low RPM cruise since the manifold is at a lower intake temp. This causes high IAT2s which is horrible on a blower car as intake temps are the enemy and cause timing to be pulled and HP to drop. It's actually such a huge problem on my car I've purchased a Killer Chiller (http://killerchiller.com/) and will be installing that this winter too. For those not familiar it's a unit that uses the car's A/C to chill the supercharger coolant and it keeps IAT2 temps drastically down. My IAT2 temps cruising on the highway at 70mph on a summer day is normally around 135F. When romping on the car 140s and 150s are common and terrible because I can feel the power fade even without pulling timing. I've read people experiencing IAT2s of 150 ~ 160 at idle with cams due to reversion. Granted that will cool once you get on the throttle some and driving but how long? This might be a real issue for me. Or maybe the killer chiller will keep this under control? It's hard to know.

So my three main questions are:

1) Will cams drop my dynamic CR even further to where I will loose HP? OR will the increased air flow provided by the cams increase HP even if CR drops. Bare in mind I'm at 27.5 PSI of boost so there's plenty of air to go around the motor can consume it.

2) Drivability. Does the Crower stage 3 cam look in the realm of a cam that can be made to drive decent on the street? If not what are your suggestions?

3) How big of an issue is air intake temps with reversion?

Any other info or help is greatly appreciated.