Project Blue Ranger

5.0 AWD Ranger

| Cable X |

One of the challenges with Project Blue Ranger is that it's an older truck using a mechanical speedometer spun by a cable from

the transmission. The donor transmission / transfer case combo from the 2000 Explorer does not have any provisions for a

mechanical speedometer cable. Instead the transmission only has an Output Speed Sensor (OSS).

To overcome this I found a product called Cable X made by Abbott Enterprises. It's an electric motor that will spin the speedometer

cable based on the signal it receives from your transmission. Sounds like problem solved right? Not quite. Read on.

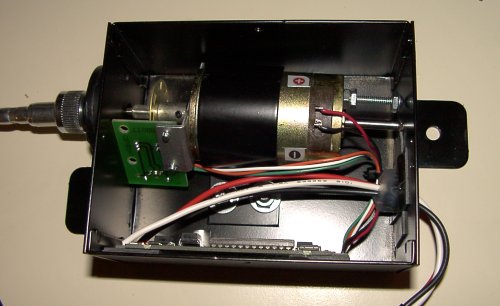

Here's what the Cable X looks like.

Here you can see the circuit board, adjustment dip switches, and the very large electric motor.

To do some initial testing and compare it to the stock factory speedometer I set up a second Ranger gauge cluster on the passenger's seat

powered by the Cable X box.

Here's where the problems started to show themselves. First the box is pretty noise and installing it in the cab is not going to be very

feasible. I will point out Abbott did tell me it was noisy up front. Yet you can't install it under the vehicle because it's not water

proof. The sugestion by Abbott was to install the box in the engine bay and run the cable straight through the firewall. Emphasis

on straight. The unit doesn't handle bends in the cable. In fact look at the picture above showing the Cable X and speedometer

on the seat of my truck. That's to much of a bend in the cable.

The problem is despite the very large electric motor it lacks the power to spin the speedometer until you get to 15~20 and sometimes

even 30 mph. At that point the needle suddenly jolts up and back down and starts displaying how fast you're going. This is very annoyning

at best. Not to mention all the bits of driving missed by the odometer, like stop and go traffic, or driving in snow, or anything that

prevents you getting above 15mph for a while.

I ended up tearing apart the whole dash trying to figure out a way to run the cable straight into the engine bay. Here's a shot of

when I got started.

Unfortunately there is absolutely NO straight shot through the firewall without putting to much curve in the cable. Every possible

angle had some sort of hang up. Even if I did find a way I was wondering where I'd put this box in the engine bay as it's rather large

and bulky.

Finally after coming up with absolutely nothing I ended up taking the Cable X unit apart and separating the electric motor and electronics

into two parts. My first attempt was to attach the electric motor directly to the back of the speedo to eliminate the cable and delay

problems at low speed. The big problem was you can only install the gauge cluster vertically and then twist upright but this is

impossible with the motor on the back.

So next I decided I'm going to have to install the electric motor into a smaller case and hopefully get it under the dash somewhere.

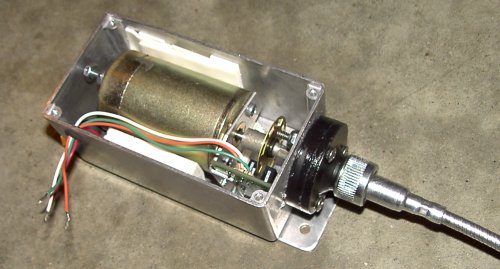

I ordered this enclosure off the internet and got it setup for the electric motor.

Since I had no idea where the final installtion would end up I supported the motor with double sided foam tape to silence the motor unlike

the original Cable X box which had the motor bolted directly to the metal case which just resonated the sound.

As you can see I transfered the cable hook up component to the new enclosure and sealed it with silicon..

Slid the wire hookups out a rubber grommet which I later sealed with silicon to make it water proof.

I ended up installing the Cable X unit in the driver's side frame rail and ran the speedometer cable up through the factory speedo

hole in the floor of the cab and up to the gauge cluster. This left me needing a cable 14" longer than the 32" supplied cable.

I called Abbott and explained I needed a 46" screw on cable to work with the Ford cable adapter they supplied with the Cable X

Unfortunately they sent me a cable like this. To short to work with the Ford adapter so off to the auto parts store to make my own

internal cable piece.

I installed the electronics under the dash in an easy to reach spot so I can play around with the dip switches.

Results:

The finished result is less than pleasing. I have a speedo that sticks until I hit 15 ~ 20mph and then suddenly snaps up and then the

needle is jittery until at least 30mph. Another very annoyning aspect is the speedo delay under acceleration and braking. It's just

not that responsive.

Abbott really needs to make some changes.

1) The motor needs to be much stronger to eliminate the need for a perfectly straight cable and

it needs to be smoother below 30mph which the current unit is not, even with the cable perfectly straight.

2) It needs to be water proofed so it can be installed under the vehicle or at the very least made quite so it can be put in the cab.

3) It needs to be much smaller.

4) There should be a remote way of adjusting the dip switches like how I installed it. No one's going to want to climb under the

vehicle to adjust the dip switches.

The good side is you can adjust the dip switches and calibrate the system very accurately. Abbott claims within 2% accuracy but I found

it to be closer to 0.2% accuracy. I was able to fine tune my speedometer very nicely.

|

|

|